The use of special heat-resistant fiber as raw material, the application of non-woven technology combines raw materials into blanket. For high temperature welding blanket, fire blanket , fire-resistant coating, heat-resistant mat, high temperature fireproof materials and other purposes. As well as green building materials, use for fireproof doors, air duct, fireproof materials, fireproof plug, interval and other security protection purposes.

Fire blanket introduction

Using special heat-resistant fiber as raw material, NON-WOVEN production technology is used to combine raw materials into a blanket, which can be used for high-temperature electric welding fireproof blanket, fire blanket (fire extinguishing blanket), flame-resistant cladding material, heat-resistant mat material, high temperature resistant fireproof material, etc. Moreover, safety protection applications such as green building materials, fireproof doors, building fire protection, fireproof materials, fireproof building materials, fireproof packing, fire compartments, etc. It can resist the instantaneous burning of 1200 °C high temperature, long-term heat resistance range of 350 ~ 450 ° C, with no burning, no melting characteristics, incineration process will not produce toxic waste gas, no secondary pollution green environmental protection materials.

| Raw material | Special heat resistant fiber. |

|---|---|

| Producing process | Needle rolling non-woven technology. |

| Use | 1. Engineering fire use: Engineering fire use: fire blanket (fire blanket), high temperature (electric welding, gas welding, sanding, cutting) fire blanket, fire curtain, heat-resistant cladding material, insulation material, heat-resistant mat, car sound insulation, heat insulation material, home fire blanket. Safety protection applications such as heat insulation blankets in high-temperature operation areas. |

| 2. Green environmental protection building materials use: Fire door materials, fire shutter doors, fire shutters, fireproof fabrics, fire curtains, and other materials, as well as building fire protection, fireproof materials, fireproof building materials, fire blockage, fire separation, and other safety protection purposes. |

Features introduction

Resistance to instantaneous burning up to 1200 ° C high temperature, high-temperature resistance 350 ~ 450 ° C. Resistant to damage. It is not embrittled, does not burn, does not melt, does not produce toxic waste gas, does not contain asbestos, and has no secondary pollution. It is foldable, easy to collect, and has appropriate weight.

Product Numbers

1. We can produce a variety of weight, specifications, length “Fire blanket” according to customer’s demand, please contact us.

| Product | Weight | Product specification | ||

| Thickness | Width | Length | ||

| Fireproof blanket | around 500g/m2 | 1.5 mm | 54″ ~ 59″ | Length can be adjusted according to demand |

| 2.0 mm | ||||

| 2.5 mm | ||||

| 3.0 mm | ||||

2. We can produce a variety of weight, specifications, length “Electric welding fire blanket” according to customer’s demand, please contact us.

| Product | Weight | Product specification | ||

| Thickness | Width | Length | ||

| Electric welding fire blanket | around 500g/m2 | 3.0 mm | 54″ ~ 59″ | Length can be adjusted according to demand |

| 4.0 mm | ||||

| 5.5 mm | ||||

| 6.0 mm | ||||

| 7.0 mm | ||||

| 8.0 mm | ||||

1. NAN YA-Fire blanket

The three elements of fire burning are heat, fuel, oxygen. The fire blanket is a safety device of fire-fighting for the home kitchen. It is a flame retardant material, and it is placed on the fire source to cut off the oxygen supply to the fire. NAN YA fire blankets can be used in home kitchens for safe protection. NAN YA fire blankets are usually made of non-woven fireproof fibers and are folded for easy storage and easy reaching.

NAN YA fire blanket using methods:

1. To completely cover the burning object.

2. Place it tightly on the surface of the burning object

Using special heat-resistant fiber as raw material. NON-WOVEN production technology is used to combine raw materials into a blanket, which can be used for a fireproof blanket, flame-resistant cladding material, heat-resistant mat material, high-temperature fireproof material, etc. for safety protection purposes. It can resist the instantaneous burning up to 1200 °C high temperature, long-term heat resistance range of 350 ~ 450 ° C. With no burning, no melting characteristics, incineration process will not produce toxic waste gas, no secondary pollution green environmental protection materials.

2.NAN YA fire blanket fire test:

1. Fire resistance: Tested by CNS 10285 L3196 A4 by Textile Synthesis Institute, rating 1 grade.

2. Flame resistance: Tested by CNS 7614 A3125 pre-treatment A method, rating 1 grade.

3. Oxygen limit index: tested by ASTM D2863 method with an index of 45 ↑.

3. The purchase numbers and specifications are as follows

NAN YA fireproof Blanket can also be used to meet various customer requirements (thickness, width, density) and welcome any inquiries for the price of post-processing and fire blanket (fire blanket), please contact us.

| Products | Weight | Product specification | ||

| Thickness | Width | length | ||

| Fireproof blanket | around 200g/m2 ~ around 500g/m2 | 1.5 mm | 54″ ~ 59″ | Length can be adjusted according to demand |

| 2.0 mm | ||||

| 2.5 mm | ||||

| 3.0 mm | ||||

NAN YA-Welding Fire Blankets

NAN YA electric welding fire blanket is the highest level, first-class fire safety material, electric welding/welding/ safety protection has a wide range of applications. Product use areas such as “industrial safety” fire retardant project. Engineering opens fire blanket (electric welding, gas welding, sanding, high-temperature cutting) safety protection. NAN YA High-Temperature Welding Fireproof Blanket is a specially treated (heat resistant synthetic fiber) with compact structure and high-temperature resistance. It can safely protect objects from heat, spark zone and completely prevent combustion or isolate combustion, adapt to electric welding.

◆Formosa Plastics Liuguang, Formosa Plastics Steel, NAN YA Plastic Fire Protection Project:

Important pipelines, production equipment, cladding, and other fire prevention measures. Insulation for mental and where welding is required.High-temperature operation area heat insulation, heat-resistant cladding materials, building materials, heat-resistant mats, sound insulation, heat insulation materials, Taiwan plastic electric vehicle battery coating, etc., showing safe and complete protection and adaptability.

◆Diversified applications :

It can be applied in fireproof building materials, heat insulation grade, fireproof grade, industrial fireproof and heat insulation materials, green building materials, medical use, etc., aerospace industrial applications, safety protection products.

NAN YA fire blanket fire test :

NAN YA electric welding/welding/ cutting fire blanket: convenient fire blanket (fire blanket) to provide you with the most comprehensive welding/safety protection. All materials are non-combustible and meet the Class 1 flame resistance standards.

| Tested by the Textile Synthesis Institute: |

|---|

| 1.Fire resistance: CNS 10285 L3196 A4, rating grade 1 fire resistance standard. |

| 2.Flame resistance: CNS 7614 A3125, rating grade 1 fire resistance standard. |

| 3.Oxygen limit index: ASTM D2863, law test index 45 ↑. |

| Characteristics: |

|---|

| 1. The thickness is from 1.0mm to 5.0mm, and the high-temperature slag resistance is long, and it is not easy to be penetrated by the slag. |

| 2.High-temperature resistance 350~450°C, anti-instantaneous burning 1200°C high temperature. |

| 3.Durable, not easy to break, not embrittled, not burning, not melting, no toxic waste, no secondary pollution, no asbestos. |

| 4.Foldable and easy to collect. The weight is appropriate. |

Scope of application:

Scope of application: NAN YA high-temperature electric welding fire blanket product application areas such as “industrial safety” fire extension project, engineering fire blanket (electric welding, welding, gas welding, sanding, high-temperature cutting) safety protection.

| NAN YA High-temperature electric welding cutting fire blanket, fire blanket “For industrial safety” | |

|---|---|

| 1. Shipbuilding industry | The shipbuilding industry is concerned with the construction and repair of the ship’s frame. |

| 2. Oil, steel, chemical companies | It has a good safety protection adaptability for heat insulation and welding where metal structures are required. |

| 3. Important equipment fire barrier | It is flexible and ideal for dressing uneven objects and equipment on the surface. It can also replace fireproof fabrics with low fire resistance. It is a more economical fire barrier and fire curtain. |

| 4.Large supermarkets, shopping malls, hotels, entertainment venues | When performing works that need to use fire: such as electric welding, cutting and blocking safety protection, the safety of people and the integrity of property can be guaranteed. |

The purchase number and specifications are as follows:

Nan YA “high-temperature electric welding/welding/ cutting fire blanket” can be customized to meet the needs of customers (various thickness, width, density), please contact us.

| Product | Weight | Product specification | ||

| Thickness | Width | Length | ||

| Electric welding fire blanket | around 500g/m2 ~ around 1000g/m2 | 3.0 mm | 54″ ~ 59″ | Length can be adjusted according to demand |

| 4.0 mm | ||||

| 5.0 mm | ||||

| 6.0 mm | ||||

| 7.0 mm | ||||

| 8.0 mm | ||||

Non-woven fire blanket performance and test description meeting

Using special heat-resistant fiber as raw material, NON-WOVEN production technology is used to combine raw materials into a blanket, which can be used for safety protection purposes such as fireproof blanket (fire extinguishing blanket), flame-resistant cladding material and heat-resistant mat. It can resist the instantaneous burning temperature up to 1200 °C, long-term heat resistance range of 350 ~ 450 ° C, with no burning, no melting characteristics, incineration process will not produce toxic waste gas, no secondary pollution.

Test items and conditions

| NO. | Fire insulation material source | Fire source type | Temperature | Contact time | Fire insulation material status |

|---|---|---|---|---|---|

| 1 | Commercial General grade Heat preservation, heat insulation, sound insulation | blowtorch | 600℃ | 4sec | Burning, holes, black smoke, melting. |

| 2 | Commercial sale of fire, heat insulation, insulation blanket | 600℃ | 18sec | Do not burn, hole, white smoke, melt. | |

| NAN YA | NAN YA fire blanket(developed by Shulin factory ) | 635℃ | 2 min | No burning, no melting, no exhaust gas, carbonization at 1000 °C. | |

| 1100℃ | |||||

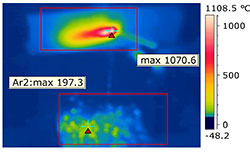

| NAN YA fire blanket(developed by Shulin factory ) | Electric welding slag ( Drop height 40cm) | 1070℃ | 30sec | No burning, no melting, no waste gas generation, reducing the height and range of electric welding slag bounce. | |

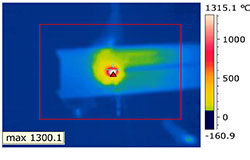

| 1300℃ | |||||

| Remarks | 1. Thermal image comparison map of the fire blanket test 1: blowtorch 600 ℃ X2min, Thermal image 1 , 2 , 3. Table 2: blowtorch 1100 ℃ X2min, Thermal image 4 , 5 , 6. Table 3: Electric welding 1070 ℃ X30sec, Thermal image 7. Table 4: Electric welding 1300 ℃ X30sec, Thermal image 8. 2.Conditional testing according to the Safety and Health Department 3. The live test will proceed on the day and a DVD is available upon request. | ||||

Fire resistance test

Weaving general office comprehensive test

Fire resistance:

1. Tested by CNS 10285 L3196 A4

2. Rating grade 1

Flame resistance:

1. Tested by CNS 7614 A3125 pre-treatment A method

2. Rating grade 1

Oxygen limit index: Tested by ASTM D2863 method, index 45↑

Test Results

1. The fireproof blanket developed by the Shulin factory is tested by the high-temperature burning test of a blowtorch. It is more durable, harder to break, does not prolong the burning, does not melt, and does not produce toxic waste gas, causing secondary pollution.

2. The fireproof blanket electric welding test proofs that it can reduce the bounce height and range of the electric welding slag.

3. The weight is proper. It is also foldable and easy to preserve. It does not have the disadvantages of easy embrittlement of glass fiber, asbestos-free and restricted substances.

4. Wide range of applications such as engineering open flame fire blankets (electric welding, gas welding, sanding, high-temperature cutting) Fire curtains, heat-resistant cladding materials, insulation materials, heat-resistant mats, automotive sound insulation, insulation materials, high-temperature operation area insulation blankets, household fire extinguishing.

5. Weaving general office test gave CNS 10285 L3196 A4、CNS 7614 A3125 first-grade evaluation. Oxygen limit index: ASTM D2863 method index 45↑

Fire resistance test

HFR-030 flame measurement :

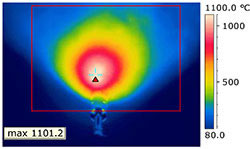

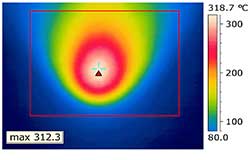

Table 1: Blowtorch 600 ° CX2min, thermal image

[Figure 1] Thermal Image (Start)

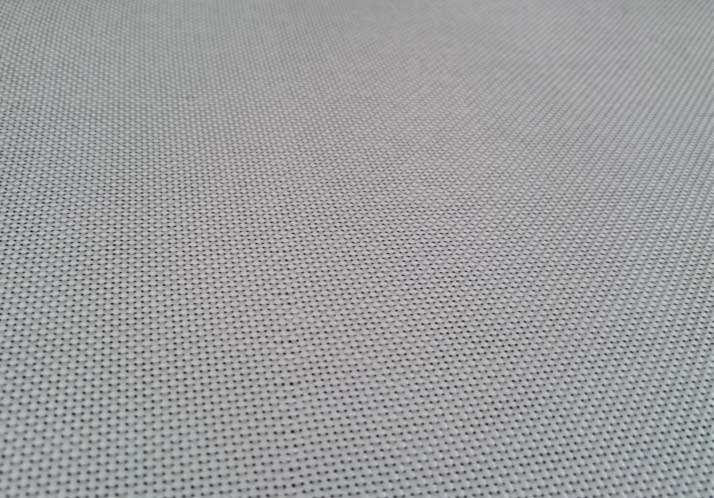

| NO. | Visible light image | Thermal image |

|---|---|---|

| 1 |  Description: Test sample 1. (Start) Description: Test sample 1. (Start) |  Measuring area surface maximum temperature: 615.6 °C Measuring area surface maximum temperature: 615.6 °C |

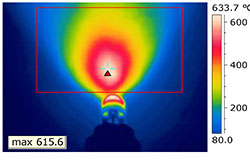

[Fig. 2] Thermal image (under test)

| No. | Visible light image | Thermal image |

|---|---|---|

| 2 |  Description: Test sample 1. (Testing) Description: Test sample 1. (Testing) |  Measuring surface maximum temperature: 635.0 °C |

[Fig. 3] Thermal image (end)

| No. | Visible light image | Thermal image |

|---|---|---|

| 3 |  Description: Test sample 1. (Finished) |  Measuring area surface maximum temperature: 312.3 °C |

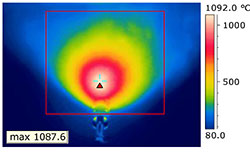

Table 2: Blowtorch 1100°CX2min, thermal image

[Figure 4] Thermal Image (Start)

| No. | Visible light image | Thermal image |

|---|---|---|

| 4 |  Description: Test sample 2. (Start) |  Measuring surface maximum temperature: : 1087.6 °C |

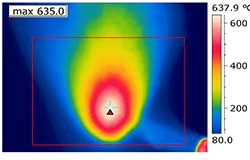

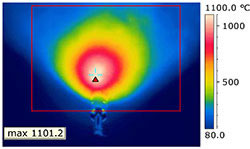

[Fig. 5] Thermal image (under test)

| No. | Visible light image | Thermal image |

|---|---|---|

| 5 |  Description: Test sample 2. (Testing) |  Measuring surface maximum temperature: 1101.2 °C |

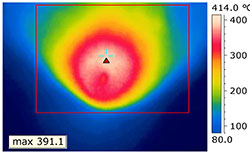

[Fig. 6] Thermal image (end)

| No. | Visible light image | Thermal image |

|---|---|---|

| 6 |  Description: Test sample 2. (Finished) |  Measuring area surface maximum temperature: 391.1 °C |

Table 3: Welding 1070 ° CX30sec, thermal image

[Figure 7] Thermal image

| No. | Visible light image | Thermal image |

|---|---|---|

| 7 |  Description: Welding workpiece temperature Description: Welding workpiece temperature Current: 140A Electrode: ψ 2.8mm |  Measuring surface maximum temperature: : 1087.6 °C |

Table 4: Welding 1300 ° CX30sec, thermal image

[Figure 8] Thermal image

| No. | Visible light image | Thermal image |

|---|---|---|

| 8 |  Description: Welding workpiece temperature Current: 140A Electrode: ψ 2.8mm |  Measuring surface maximum temperature: :>1300.1°C |